Electronic Manufacturing Services - What Is It?

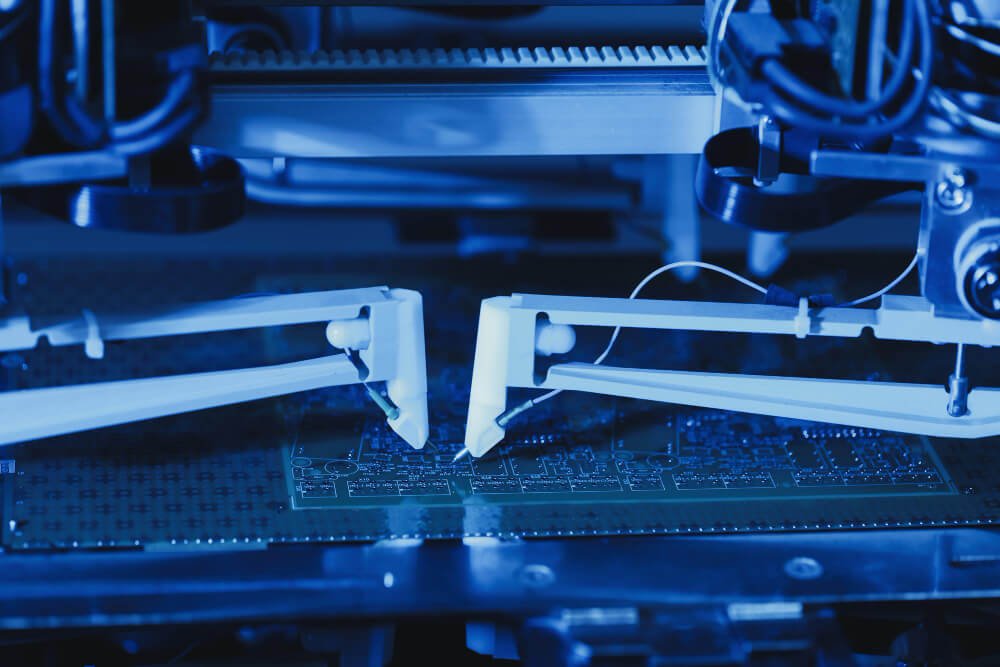

EMS

EMS (Electronics Manufacturing Service) means a service of manufacturing electronic devices. Leading IT and automobile companies are now using EMS manufacturers around the world in order to plan, develop and execute the creation of a new electronic product. In this article, we’ll talk about:

- What is EMS?

- Why it’s trending?

- EMS Advantages

EMS is a manufacturing business model. In the case of cooperating factories, the manufacturer specifies the parts to be used in the product. However, in Electronic Manufacturing Services procedure, the consignee gets the parts and materials through its own channels. EMS is often confused with OEM, but they are entirely different.

Why EMS is Trending?

In the manufacturing market, where new products are being introduced one after another, electrical devices’ lifespan is by no mens long. To be able to change rapidly as the changing markets, electronics manufacturing companies are constantly creating new electrical appliances that can result in huge costs.

Therefore, many electronic equipment manufacturers have implemented EMS in order to organize their management resources. The electronic manufacturing service will outsource it to a company that specializes in manufacturing rather than spending time, money and energy maintaining their own factory.

EMS Advantages

In this section, we will look at the benefits resulting from implementing EMS on both sides – The outsourcer and contractor.

Outsourcing Companies

First of all, there are two major advantages to EMS from the perspective of the consignment company.

- Reduced costs

- Avoid unnecessary risks

Reduced Costs

By adopting an EMS to outsource the manufacturing processing, it is possible to reduce capital investment or labor costs and to group management resources.

Avoid Unnecessary Risks

The market speed is dizzying, and existing products can quickly become obsolete due to changes in demand or technology improvements. It is quite difficult to make capital investment in line with the changing markets, but if we outsource manufacturing, we can avoid risks in advance and respond quickly to changes.

Contractor Company

- Reduced costs

- Acquire technology and practices

Reduced Costs

EMS contractors can manufacture a wide variety of products beyond the boundaries of manufacturers. Therefore, the more the production volume increases, the more the procurement cost can be reduced by purchasing parts in large quantities.

Acquire Technology and Practices

Contracted companies can accumulate technology and knowledge necessary for EMS production. Recently, some EMS manufacturers have started selling their own branded products.

EMS Disadvantages

In EMS, the contracting company cannot directly give instructions to the consignment side.It can be said that it is a disadvantage for both sides because it will take longer time to notice and fix any production problem.